Why Battery Watering is Important

Electric forklift batteries, typically lead-acid, rely on an electrolyte solution composed of sulfuric acid and water to produce power. Over time, the water component evaporates, especially during charging. Without adequate water levels, the battery’s lead plates can be exposed, leading to sulfation, reduced performance, and even permanent damage.

Proper watering is essential to maintain the right electrolyte levels, ensuring that the battery can produce consistent power and achieve its full lifespan. Neglecting or improperly watering batteries can lead to frequent repairs, costly replacements, and more downtime for your forklifts.

When to Water Electric Forklift Batteries

1. Prioritize Watering After a Full Charge:

- It is best to water forklift batteries immediately after they have been fully charged. During charging, the electrolyte expands, so filling the cells beforehand can cause overflow, which damages the battery and creates a hazardous environment.

2. Establish a Consistent Watering Schedule:

- Depending on usage, most forklift batteries require watering every week or two. For heavy-use fleets, this might mean checking water levels every few days, while lighter use might only require weekly checks.

How to Water Electric Forklift Batteries

1. Check your water:

- Tap water contains minerals that can damage the battery’s internal components and reduce its lifespan. Plan to use distilled or deionized water, which is free from impurities that could harm the battery. A building may have a water filtration system installed to filter out some impurities in the tap water, if that is the case the water should be tested but may otherwise be totally fine to use.

2. Fill to the Correct Level:

- Ensure the water level reaches just above the battery’s lead plates, covering them completely without overfilling. Overfilling can cause electrolyte spills, and underfilling can expose the plates, leading to sulfation and reduced battery performance.

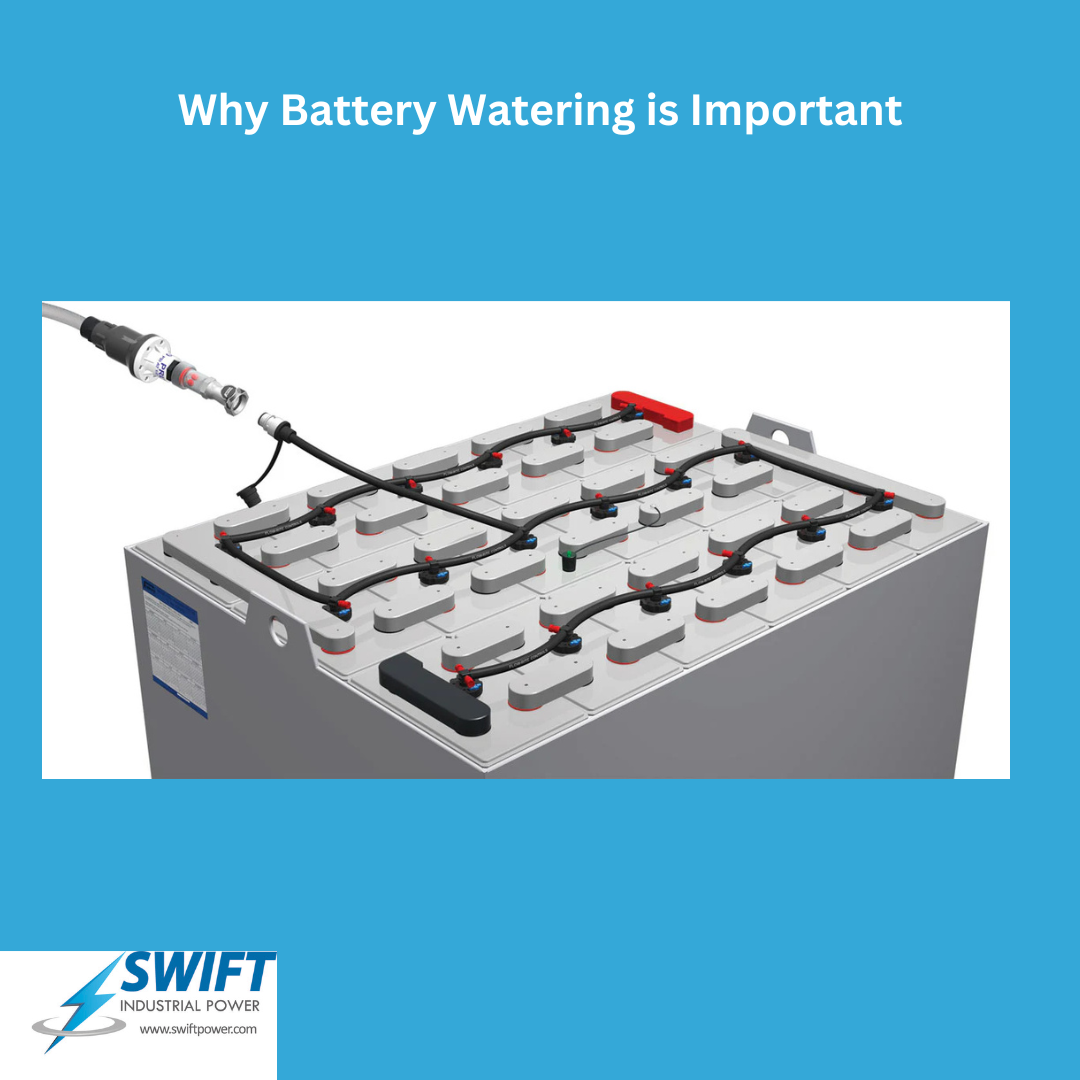

3. Invest in a Battery Watering System:

- Manual watering can be time-consuming and prone to error, especially in large fleets. A battery watering system simplifies the process, ensuring each cell is filled to the correct level and reducing the risk of over- or under-filling.

Essential Tips for Safe and Effective Battery Watering

1. Wear Protective Gear:

- Battery electrolyte is highly corrosive. Always wear gloves, safety goggles, and appropriate clothing when checking or filling water levels to prevent injuries.

2. Inspect Batteries Regularly:

- When watering batteries, inspect them for any signs of leaks, corrosion, or damage. Look for cracked casings, corroded connectors, or frayed cables. Identifying issues early can prevent larger, costlier problems.

3. Avoid Battery Opportunity Charging:

- Opportunity charging, or frequently “topping off” the battery charge, can increase water consumption and shorten battery life.

4. Maintain a Clean Battery Bay:

- Battery spills or leaks can lead to corrosion and hazardous working conditions. Keep the battery bay clean and ensure any spilled electrolyte is neutralized and wiped away immediately. Regularly inspect for signs of acid accumulation and clean it with a baking soda and water solution if needed.

Common Battery Watering Mistakes to Avoid

1. Watering Before Charging

- Filling the battery before charging can lead to overflow during the charging process. This damages the battery and creates a risk of acid spills. While it may not always be practical, watering after a full charge is preferred.

2. Using the Wrong Water Type

- Minerals in tap water can significantly harm battery health. Plan on distilled water to avoid impurities that can degrade battery cells. As referenced above, tap water can be tested to ensure it meets the requirements which is no problem as long as it’s verified.

3. Over-Watering or Under-Watering

- Consistency is key. Over-watering leads to spills and corrosion, while under-watering exposes plates to air, increasing the risk of sulfation and reducing the battery’s lifespan. Aim for a level just above the plates each time.

4. Ignoring Battery Temperature

- Charging batteries when they’re too hot can increase water evaporation, so it’s best to let batteries cool before charging. Keep the battery storage area at a stable temperature between 60°F and 77°F to avoid excess water loss due to heat.

Conclusion

Maintaining proper water levels in your electric forklift batteries is essential for maximizing efficiency, performance, and lifespan. By following these best practices—using proper water, establishing a regular watering schedule, and investing in an automatic watering system—you can reduce downtime, cut maintenance costs, and keep your fleet running strong.

Battery watering doesn’t have to be complex, but it does need to be consistent and thorough. Proper battery care ultimately translates to safer, more efficient, and cost-effective operations, making it worth the effort.

Want to take the guess work out of watering? Contact our staff of trained professionals who can set you up on a recurring schedule and help maintain your fleet.