Top Benefits of Using a Battery Watering System for Electric Forklift Batteries

Electric forklifts have become essential in modern warehouses and distribution centers, offering efficient and eco-friendly solutions for material handling. The longevity and performance of electric forklift batteries are crucial to maintaining operational efficiency. One effective way to ensure optimal battery performance is by implementing a battery watering system. Here, we explore the top benefits of using a battery watering system for electric forklift batteries.

1. Improved Battery Lifespan

Regular maintenance is key to prolonging the life of electric forklift batteries. A battery watering system automates the process of adding water to lead-acid batteries, ensuring that electrolyte levels remain optimal. Consistently maintaining proper water levels prevents over-discharging and minimizes the risk of sulfation, ultimately extending the life of your batteries.

2. Enhanced Efficiency

Manual watering of batteries can be time-consuming and prone to human error. A battery watering system streamlines the process, allowing for quick and efficient maintenance. This automation not only saves time but also ensures that batteries are watered at the right intervals, leading to better overall performance and reduced downtime in operations.

3. Reduced Labor Costs

By automating the watering process, businesses can save on labor costs associated with manual maintenance. With less time spent on battery upkeep, staff can focus on other critical tasks, improving overall productivity. Additionally, fewer maintenance-related errors can lead to lower operational costs in the long run.

4. Enhanced Safety

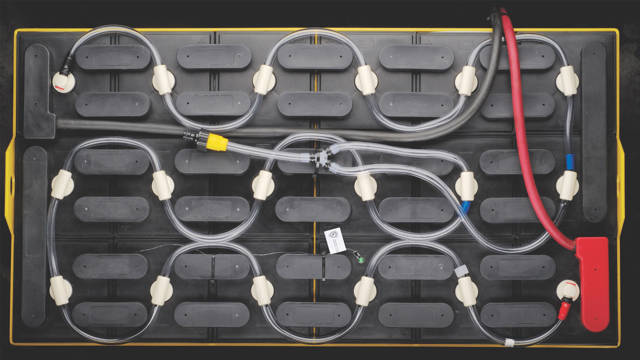

Battery maintenance can be hazardous, especially when handling corrosive electrolyte solutions. A battery watering system minimizes the need for direct contact with battery fluids, reducing the risk of spills and potential injuries. Moreover, these systems often come with built-in safety features, such as automatic shut-off valves, which prevent overfilling and ensure safe operation.

5. Consistent Watering

Inconsistent watering can lead to uneven battery performance and premature failure. A battery watering system ensures that each cell receives the appropriate amount of water, promoting balanced charging and discharging cycles. This consistency helps maintain the overall health of the battery and enhances its operational efficiency.

6. Environmental Benefits

Properly maintained batteries are not only beneficial for your operations but also for the environment. A battery watering system helps prevent the overuse of water and reduces the risk of hazardous leaks, aligning with sustainability goals and promoting a safer workplace.

7. Ease of Use

Modern battery watering systems are designed for user-friendly operation, often featuring simple controls and indicators that make it easy to monitor water levels and maintenance needs. This ease of use encourages regular maintenance, further contributing to improved battery performance.

Conclusion

Implementing a battery watering system for electric forklift batteries offers numerous benefits, from enhanced efficiency and safety to prolonged battery life and reduced labor costs. By investing in this technology, businesses can optimize their operations, ensure consistent performance, and contribute to a safer, more sustainable working environment. Explore the options available for battery watering systems and take a proactive step toward improving your battery maintenance practices today!

We offer a full suite of maintenance solutions including Preventative Maintenance, Watering, and the full package with Total Maintenance. Check out our service offering!