Forklift Battery Watering Systems: An Essential Guide for Optimal Performance

Forklifts are the backbone of material handling in various industries, and their efficiency hinges on the condition of their batteries. One often-overlooked aspect is the watering system. This guide explores the importance of forklift battery watering and watering systems and their role in ensuring optimal performance.

Understanding Forklift Batteries:

Forklifts typically use lead-acid batteries known for their reliability. As these batteries operate, water within them evaporates, affecting performance and lifespan. Proper maintenance, especially regular watering, is crucial for peak performance.

The Role of Forklift Battery Watering Systems:

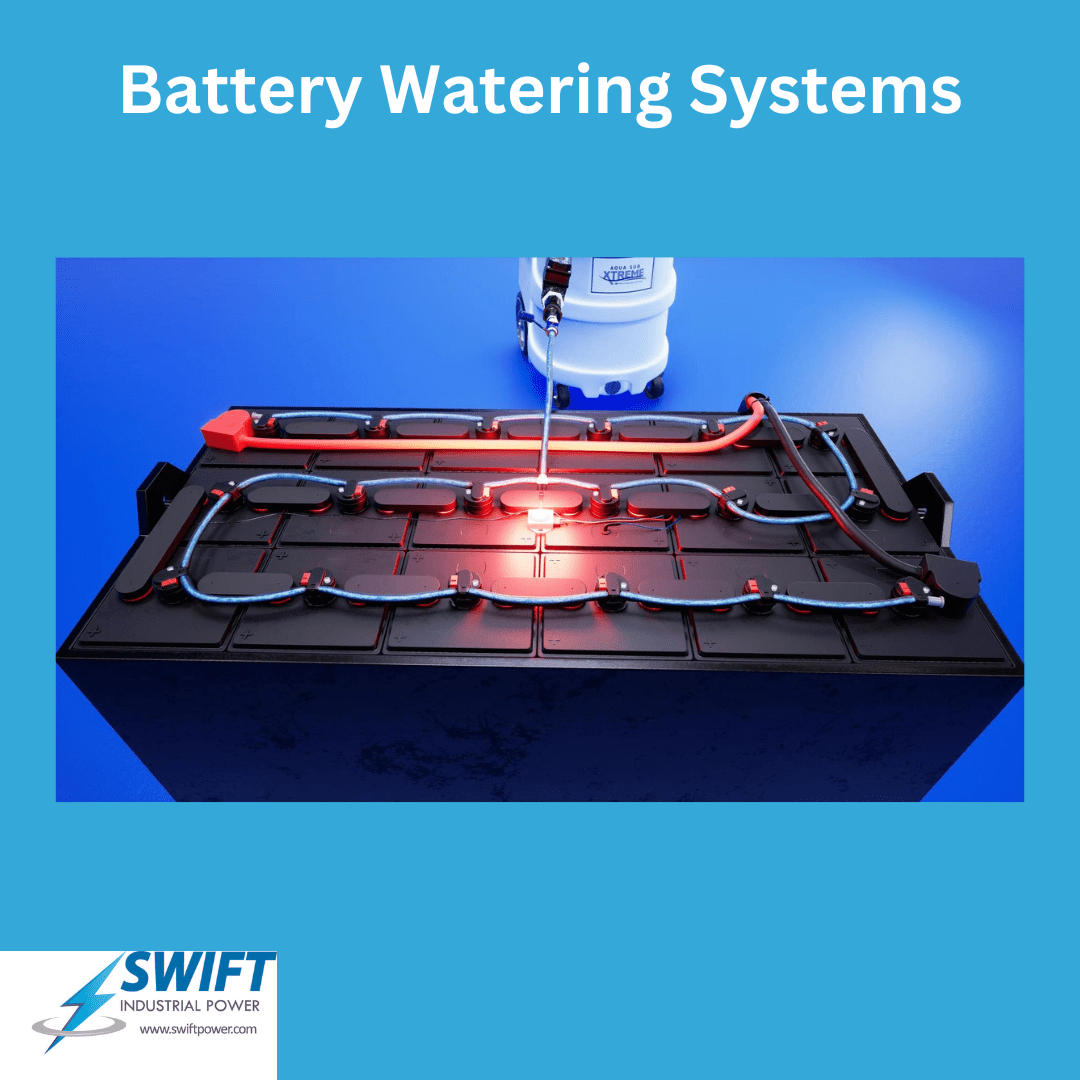

These systems simplify maintenance by automating the watering process. Comprising valves, tubing, and water delivery devices, they ensure each battery cell receives the right amount of water without spills.

Benefits of Forklift Battery Watering Systems:

- Enhanced Safety: Closed-system design reduces the risk of acid exposure and spills, creating a safer workplace.

- Time and Labor Savings: Automation saves time and reduces manual labor, allowing for more efficient resource use.

- Consistent Watering: Ensures accurate water delivery to each cell, preventing under or over-watering for even battery performance.

- Extended Battery Life: Contributes to prolonged battery and forklift lifespan, reducing replacement costs.

- Improved Performance: Well-maintained batteries lead to efficient forklift performance, increasing productivity in material handling operations.

Installation and Maintenance Tips:

- Follow Manufacturer Guidelines: Adhere to the forklift battery manufacturer’s guidelines and specifications for the specific watering system to ensure proper installation.

- Regular Inspections: Schedule routine inspections to identify and address any issues promptly. Check for clogs, leaks, or malfunctions in the watering system.

- Use Deionized or Distilled Water: Always use deionized or distilled water to refill battery cells, as impurities in tap water can lead to mineral buildup and damage the battery.

Ready to take your forklift battery fleet to the next level? Check out our battery watering systems and comprehensive scheduled maintenance services. Ensure your forklifts operate at peak performance, minimize downtime, and extend the lifespan of your batteries. Contact us today to schedule a consultation and experience the difference our solutions can make for your business.